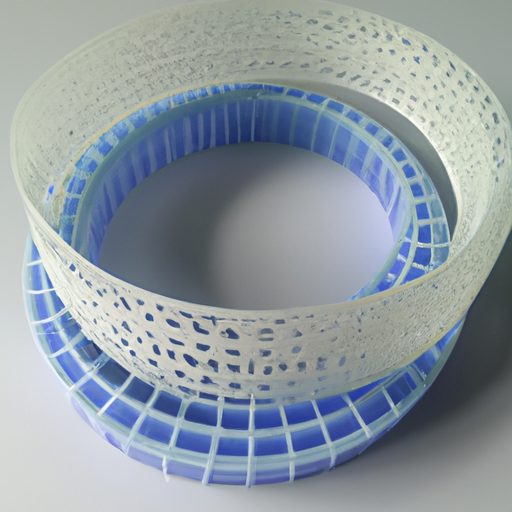

Application Development in Double Layer Silicone Fiberglass Sleeving for SB-TGS-2S: Key Technologies and Success Stories

Double Layer Silicone Fiberglass Sleeving, such as the SB-TGS-2S, represents a significant advancement in materials designed for high-temperature applications. This specialized sleeving combines the robust thermal resistance of fiberglass with the flexibility and chemical resilience of silicone, making it suitable for a wide range of demanding environments. Below, we explore the key technologies that underpin this material and highlight notable success stories from various industries.

Key Technologies

| 1. Material Composition | |

| 2. Manufacturing Techniques | |

| 3. Thermal Insulation | |

| 4. Electrical Insulation | |

| 5. Customization | |

| 1. Aerospace Industry | |

| 2. Automotive Applications | |

| 3. Industrial Equipment | |

| 4. Renewable Energy | |

| 5. Consumer Electronics |

Success Stories

Conclusion

The development and application of Double Layer Silicone Fiberglass Sleeving, such as SB-TGS-2S, underscore the importance of advanced materials in high-temperature environments. Its unique combination of thermal and electrical insulation properties, along with its flexibility and chemical resistance, makes it a valuable solution across various industries. The success stories illustrate its versatility and effectiveness in enhancing the performance and reliability of critical systems. As technology continues to evolve, further innovations in materials and applications are expected, expanding the potential uses of this high-performance sleeving and solidifying its role in future advancements.