Application Development in Silica Fiber Braided Sleeve for SB-SGS-EX Expandable Silicone Fiberglass Sleeving: Key Technologies and Success Stories

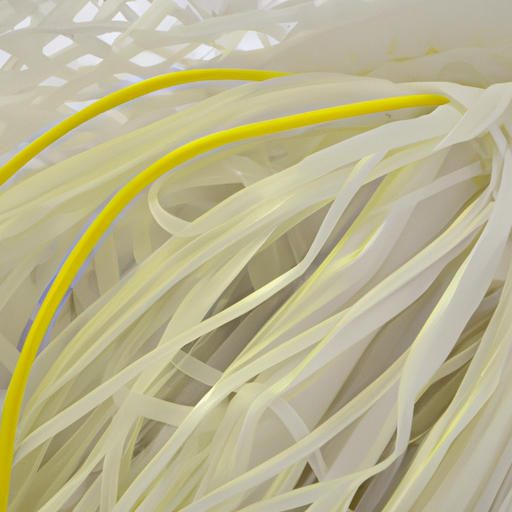

The development of applications using Silica Fiber Braided Sleeving, particularly the SB-SGS-EX Expandable Silicone Fiberglass Sleeving, is driven by several key technologies and methodologies. This overview highlights critical aspects of these materials and showcases success stories that demonstrate their effectiveness across various industries.

Key Technologies

| 1. Material Composition | |

| 2. Braiding Techniques | |

| 3. Expandable Design | |

| 4. Thermal and Electrical Insulation | |

| 5. Chemical Resistance | |

| 1. Automotive Industry | |

| 2. Aerospace Applications | |

| 3. Industrial Equipment | |

| 4. Marine Applications | |

| 5. Renewable Energy Sector |

Success Stories

Conclusion

The development and application of Silica Fiber Braided Sleeving, particularly the SB-SGS-EX Expandable Silicone Fiberglass Sleeving, underscore the significance of advanced materials in enhancing the performance and reliability of systems across multiple industries. The combination of high-temperature resistance, flexibility, and chemical durability positions these sleeves as a valuable solution for protecting critical components in challenging environments. As industries continue to evolve, the demand for such innovative materials is expected to grow, paving the way for further advancements and success stories in application development.