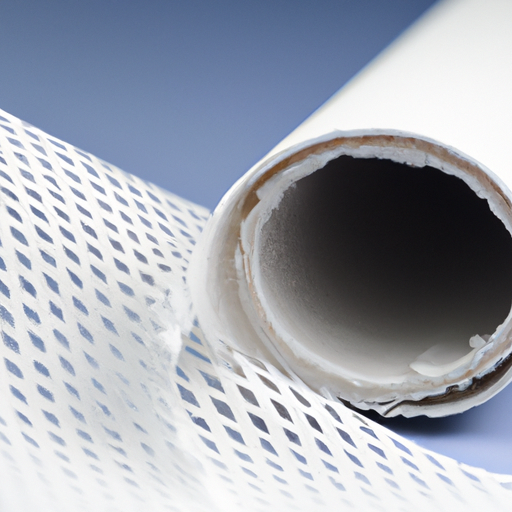

Application Development in PU Fiberglass Sleeving for SBD-CSSP

The integration of Polyurethane (PU) fiberglass sleeving in Small Business Development - Cybersecurity Service Provider (SBD-CSSP) applications represents a significant advancement in protective solutions for electrical and electronic components. This document outlines the key technologies involved in the development of PU fiberglass sleeving and highlights notable success stories across various industries.

Key Technologies

| 1. Material Composition | |

| 2. Manufacturing Techniques | |

| 3. Thermal and Electrical Insulation | |

| 4. Customization and Scalability | |

| 5. Testing and Quality Assurance | |

| 1. Automotive Industry | |

| 2. Aerospace Applications | |

| 3. Consumer Electronics | |

| 4. Industrial Equipment | |

| 5. Telecommunications |

Success Stories

Conclusion

The development of PU fiberglass sleeving for SBD-CSSP applications exemplifies the convergence of advanced materials science and practical engineering solutions. By focusing on key technologies and learning from successful implementations across various industries, businesses can enhance their product offerings and improve performance in challenging environments. As the demand for reliable and durable protective solutions continues to rise, the potential for innovation in this field remains substantial, paving the way for future advancements in material technology and application development.