SBD-FEP Double Layer Acrylic Fiberglass Sleeving: Core Functional Technology and Application Development

Introduction to SBD-FEP Double Layer Acrylic Fiberglass Sleeving

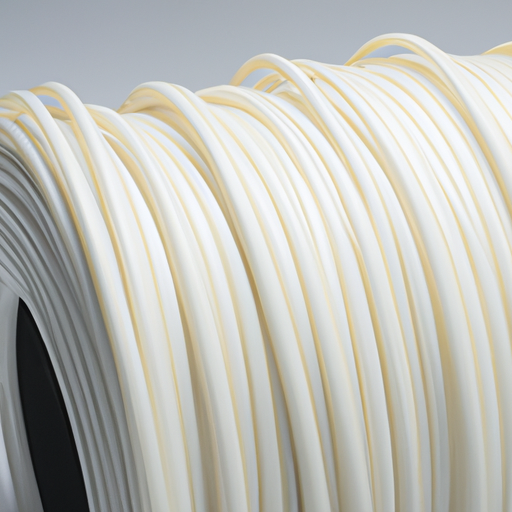

SBD-FEP (Fluorinated Ethylene Propylene) Double Layer Acrylic Fiberglass Sleeving is a cutting-edge insulation material engineered to deliver exceptional thermal and electrical protection across a variety of industrial applications. By integrating the robust properties of fiberglass with the advanced chemical resistance and thermal stability of FEP, this sleeving is ideally suited for high-performance environments.

Core Functional Technology

| 1. Material Composition | |

| 2. Thermal Resistance | |

| 3. Electrical Insulation | |

| 4. Chemical Resistance | |

| 5. Flame Retardancy | |

| 1. Aerospace Industry | |

| 2. Automotive Sector | |

| 3. Industrial Machinery | |

| 4. Telecommunications | |

| 5. Medical Devices |

Application Development Cases

Conclusion

SBD-FEP Double Layer Acrylic Fiberglass Sleeving represents a significant advancement in insulation technology, merging the strengths of fiberglass and FEP to meet the rigorous demands of various industries. Its core functional technologies—including thermal and electrical resistance, chemical stability, and flame retardancy—make it an effective solution for challenging applications. The successful development cases across aerospace, automotive, industrial, telecommunications, and medical sectors underscore its versatility and effectiveness in enhancing performance and safety in critical environments. As industries continue to evolve, SBD-FEP sleeving stands out as a reliable choice for high-performance insulation needs.