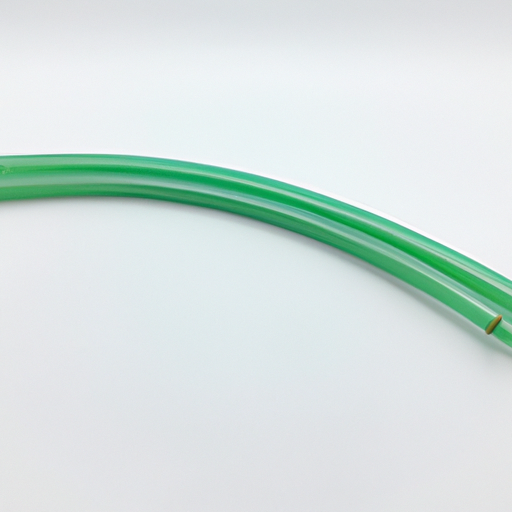

SBD-NSHST Nonslip Heat Shrink Tube Fiberglass Sleeving highlighting the core functional technology articles and application development cases of Fiberglass Sleeving that are effective.

2025-07-23 03:44

SBD-NSHST Nonslip Heat Shrink Tube Fiberglass Sleeving: Core Functional Technology and Application Development

Core Functional Technology

| 1. Material Composition | |

| 2. Nonslip Surface | |

| 3. Electrical Insulation | |

| 4. Chemical Resistance | |

| 5. Thermal Protection | |

| 1. Aerospace Industry | |

| 2. Automotive Sector | |

| 3. Industrial Machinery | |

| 4. Renewable Energy | |

| 5. Marine Applications | |

| 6. Electronics |

Application Development Cases

Conclusion

The SBD-NSHST Nonslip Heat Shrink Tube Fiberglass Sleeving represents a significant advancement in protective sleeving technology. Its unique combination of heat resistance, electrical insulation, chemical resistance, and nonslip properties makes it an effective solution for a wide range of applications across various industries. As technology continues to evolve, the development and application of fiberglass sleeving will likely expand, addressing new challenges and enhancing the performance of electrical and mechanical systems. The versatility and reliability of SBD-NSHST ensure it remains a critical component in the design and protection of modern electrical systems.